PolySeal Clear Wood Finish: Thicker, fuller body - less mess, less drip

You’re going to love all the practical application benefits of PolySeal.

PolySeal’s many great features include exceptional appearance, ease of application and user-friendly low fume, clean air formulas. Once dried, the PolySeal formulas will provide an excellent nonporous barrier for cleaning and dusting.

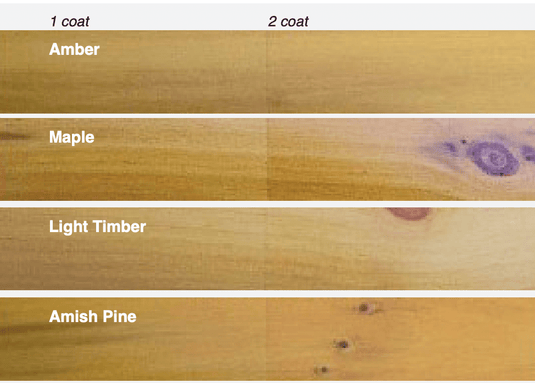

The Wall & Woodwork formulas are available in transparencies of clear Crystal, honey Amber, honey brown Maple and light tan Amish Pine. It is designed for use on all interior bare wood surfaces including kitchen cabinetry, molding, paneling, log walls and hardwood & hard pine flooring.

When applying any of our PolySeal formulas, you’ll quickly see how user-friendly they are. They are very low in fumes and they can receive another coat within 2 to 3 hours (75°F). You don’t have to wait very long between coats which means you can get your project done that much faster and with great results.

PolySeal Clear Wood Finish Features and Benefits:

- Seals the wood pores and helps maintain an allergy free environment!

- Cleaning and dusting are more thorough and effective.

- Adds depth and clarity to the wood grain.

- Scrub and mar resistant.

- Low fume and very user friendly.

- Available in Crystal, Amber, Amish Pine and Maple transparencies.

- Dries fast – 3 to 4 coats in a day.

- Soap and water clean up.

Coverage:

250-400 square feet per gallon

Note: Crystal is available in both satin & gloss. Colors are available only in satin.

For full performance and appearance value, we recommend a minimum of 2 and preferably 3 coats for log walls & paneling, 4 coats for wood floors.

PolySeal Wall & Woodwork formula is a water-based polyurethane/acrylic varnish that is designed for use on all interior bare wood surfaces (except floors) including kitchen cabinetry, molding, paneling, log walls and front entrance doors that are not directly exposed to the elements. Its unique, full-bodied consistency is much easier and less mess to apply than your typical thin varnishes. When applying PolySeal you’ll quickly see how pleasant and low in fumes it really is. It dries fast and can be top coated normally within 2 hours which means you can get your project completed in less time and without the unpleasant side effects of mind-numbing fumes. It cures to a superdurable transparent coating that’s easy-to-clean and maintain. 2 and preferably 3 coats are recommended for best performance and appearance. Available in Crystal, Amber, Maple, and Pearl transparencies.

Note: As an option, use PolySeal’s QuikSand as your base coat.

Dry To Touch – 30-90 minutes at 70° F (21°C) and moderate humidity.

Maintenance – Keep PolySeal coated surfaces dusted and clean. For dirtier stained areas, clean with a damp sponge and mild detergent. Avoid cleaners that contain alcohol or harsh chemicals.

Theoretical Coverage – Approximately 500 sq. ft./gal. at 1.0 MIL over a non-porous surface. Actual coverage will vary according to the porosity of the wood, method of application, and applicator technique.

Clean-Up – Clean tools and equipment immediately after use with soap and water, then rinse thoroughly with clean water.

Surface Preparation – For best results, the wood surface must be dry and free from dust, grease, oil, wax, dir t, paint, and fungus. Fill holes and cracks in the wood with a quality acrylic or latex-based wood filler. Do not use wax sticks or wood fillers that contain waxes or stearate additives. Wash new wood sur faces with a cleaning solution of 4 ounces of Trisodium Phosphate (or equivalent) into one-gallon warm water and immediately rinse clean with a clean, wet sponge.

Do Not Let Cleaning Solution Dry On Surface Or Adhesion Problems Could Occur.

Lightly sand cleaned wood sur face with 60-100-grit sandpaper. Previously varnished surfaces that are in sound condition should be thoroughly sanded and wiped clean before applying PolySeal . Resin from bleeding knots should be softened and removed using

a hot air gun and scraped with a putty knife. Once cooled, wipe remaining residue clean with lacquer thinner or liquid sandpaper. Do not apply PolySeal on wood surfaces that are damp or over wood that has moisture content that exceeds 18%, otherwise moisture-related discoloration and coating problems could occur. On interior log walls, generally wait through a heating season and at least 8 months and preferably 1 year before applying PolySeal unless otherwise specified by the log home manufacturer.

Mixing – Mix thoroughly before using. Do not dilute. Soft settling can occur. Make certain to softly scrape residue off the bottom and mix thoroughly. Hand stirring or using a drill mixer until completely blended is recommended. Do not shake or otherwise create foam.

Application Guidelines – ALWAYS MAINTAIN GOOD VENTILATION! Apply with a foam pad applicator or a good quality synthetic bristle varnish brush (whichever works best in your situation). Apply in even strokes and avoid excessive brushing. PolySeal can also be applied by airless spray (.011 - .013-tip size) but is not recommended for inexperienced applicators. Also, spray applying the PolySeal colors is much more difficult to achieve an even appearance without fan marks and color variations. PolySeal will raise the grain of most hard woods and will require light sanding once dried. 180 grit 3M brand 235U green sandpaper is recommended.

NEVER USE STEEL WOOL!

For the smoothest finish, light sanding between coats is recommended although not always essential. Wait a minimum of 2 hours between coats (75°F [24°C], 50% RH). Sand in the direction of the wood grain and remove dust by vacuum and damp or tack cloth. Ideal temperature is 65°- 80°F (18°C - 27°C). Brush drag may occur when temperatures are too cold or too hot resulting in an uneven application and appearance. Because PolySeal dries fast, care must be taken to avoid lap marks, especially when applying colors. Apply PolySeal at a constant medium rate tempo and always coat the wood section to completion. Don’t stop in the middle! When reloading applicator between brush outs, start 12”-18” ahead of last application and work back to it in order to reduce likelihood of lap marks.

Important–PolySeal may react with tannins and watersoluble extractives found in certain species of wood such as red oak causing a darkening of the wood grain. Also, growing evidence seems to suggest that kiln-dried dimensional lumber (V-match paneling, etc.) that has been wetted by acid rain and then exposed to sunlight may chemically react with water-based varnishes causing blotchy discoloration that follow the pattern of the rain marks. To prevent these occurrences, use White Shellac as a base coat prior to top coating with PolySeal . Always first test a small portion of the wood to be coated with PolySeal to make certain color and appearance is suitable and to confirm that the chemical reactions mentioned above will not occur.

Caution: A slight haze in the PolySeal film can occur if more than one coat is applied too quickly without allowing the previous coat(s) to properly dry. Also, applying too thick of a coat in a single application may cause a similar effect. Do not puddle!

Avoid Prolonged Contact With Alcohol Or Alcohol-based Liquids. Wipe Up Any Alcohol Spills Immediately! Otherwise The Alcohol Can Attack And Damage The Polyseal™ Film And Will Require Sanding And Recoat To Properly Repair And Restore.

Combustible • Contains Petroleum Distillate Solvents, Alcohols, Ketones, Esters, Ethers (Alone or in combination)

See Material Safety Data Sheet

WARNING: Harmful if inhaled or absorbed through skin, causes irritation. Do not breathe vapors or spray mist. Wear an appropriate, properly fitted respirator (NIOSH-MSHA approved) during and after application unless air monitoring demonstratesvapor mist levels are below applicable limits. Follow respirator manufacturer’s directions for respirator use. Avoid contact with eyes, skin and clothing. Wash thoroughly after handling. Keep away from heat and flames. Use with adequate ventilation. Keep containers closed when not in use. In case of spillage, absorb with inert material and dispose of in accordance with applicable regulations.

First Aid: In case of eye contact, flush immediately with plenty of water for at least 15 minutes and get medical attention. For skin, wash thoroughly with soap and water. If affected by inhalation of vapor or spray mist, remove to fresh air. If swallowed, get medical attention. Wash clothing before reuse.

Notice: Reports have associated repeated and prolonged occupational overexposure to solvents with permanent brain and nervous system damage. Intentional misuse by deliberately concentrating and inhaling the contents may be harmful or fatal. Do Not Induce Vomiting.

PolySeal Clear Wood Finish: Thicker, fuller body - less mess, less drip

You’re going to love all the practical application benefits of PolySeal.

PolySeal’s many great features include exceptional appearance, ease of application and user-friendly low fume, clean air formulas. Once dried, the PolySeal formulas will provide an excellent nonporous barrier for cleaning and dusting.

The Wall & Woodwork formulas are available in transparencies of clear Crystal, honey Amber, honey brown Maple and light tan Amish Pine. It is designed for use on all interior bare wood surfaces including kitchen cabinetry, molding, paneling, log walls and hardwood & hard pine flooring.

When applying any of our PolySeal formulas, you’ll quickly see how user-friendly they are. They are very low in fumes and they can receive another coat within 2 to 3 hours (75°F). You don’t have to wait very long between coats which means you can get your project done that much faster and with great results.

PolySeal Clear Wood Finish Features and Benefits:

- Seals the wood pores and helps maintain an allergy free environment!

- Cleaning and dusting are more thorough and effective.

- Adds depth and clarity to the wood grain.

- Scrub and mar resistant.

- Low fume and very user friendly.

- Available in Crystal, Amber, Amish Pine and Maple transparencies.

- Dries fast – 3 to 4 coats in a day.

- Soap and water clean up.

Coverage:

250-400 square feet per gallon

Note: Crystal is available in both satin & gloss. Colors are available only in satin.

For full performance and appearance value, we recommend a minimum of 2 and preferably 3 coats for log walls & paneling, 4 coats for wood floors.

PolySeal Wall & Woodwork formula is a water-based polyurethane/acrylic varnish that is designed for use on all interior bare wood surfaces (except floors) including kitchen cabinetry, molding, paneling, log walls and front entrance doors that are not directly exposed to the elements. Its unique, full-bodied consistency is much easier and less mess to apply than your typical thin varnishes. When applying PolySeal you’ll quickly see how pleasant and low in fumes it really is. It dries fast and can be top coated normally within 2 hours which means you can get your project completed in less time and without the unpleasant side effects of mind-numbing fumes. It cures to a superdurable transparent coating that’s easy-to-clean and maintain. 2 and preferably 3 coats are recommended for best performance and appearance. Available in Crystal, Amber, Maple, and Pearl transparencies.

Note: As an option, use PolySeal’s QuikSand as your base coat.

Dry To Touch – 30-90 minutes at 70° F (21°C) and moderate humidity.

Maintenance – Keep PolySeal coated surfaces dusted and clean. For dirtier stained areas, clean with a damp sponge and mild detergent. Avoid cleaners that contain alcohol or harsh chemicals.

Theoretical Coverage – Approximately 500 sq. ft./gal. at 1.0 MIL over a non-porous surface. Actual coverage will vary according to the porosity of the wood, method of application, and applicator technique.

Clean-Up – Clean tools and equipment immediately after use with soap and water, then rinse thoroughly with clean water.

Surface Preparation – For best results, the wood surface must be dry and free from dust, grease, oil, wax, dir t, paint, and fungus. Fill holes and cracks in the wood with a quality acrylic or latex-based wood filler. Do not use wax sticks or wood fillers that contain waxes or stearate additives. Wash new wood sur faces with a cleaning solution of 4 ounces of Trisodium Phosphate (or equivalent) into one-gallon warm water and immediately rinse clean with a clean, wet sponge.

Do Not Let Cleaning Solution Dry On Surface Or Adhesion Problems Could Occur.

Lightly sand cleaned wood sur face with 60-100-grit sandpaper. Previously varnished surfaces that are in sound condition should be thoroughly sanded and wiped clean before applying PolySeal . Resin from bleeding knots should be softened and removed using

a hot air gun and scraped with a putty knife. Once cooled, wipe remaining residue clean with lacquer thinner or liquid sandpaper. Do not apply PolySeal on wood surfaces that are damp or over wood that has moisture content that exceeds 18%, otherwise moisture-related discoloration and coating problems could occur. On interior log walls, generally wait through a heating season and at least 8 months and preferably 1 year before applying PolySeal unless otherwise specified by the log home manufacturer.

Mixing – Mix thoroughly before using. Do not dilute. Soft settling can occur. Make certain to softly scrape residue off the bottom and mix thoroughly. Hand stirring or using a drill mixer until completely blended is recommended. Do not shake or otherwise create foam.

Application Guidelines – ALWAYS MAINTAIN GOOD VENTILATION! Apply with a foam pad applicator or a good quality synthetic bristle varnish brush (whichever works best in your situation). Apply in even strokes and avoid excessive brushing. PolySeal can also be applied by airless spray (.011 - .013-tip size) but is not recommended for inexperienced applicators. Also, spray applying the PolySeal colors is much more difficult to achieve an even appearance without fan marks and color variations. PolySeal will raise the grain of most hard woods and will require light sanding once dried. 180 grit 3M brand 235U green sandpaper is recommended.

NEVER USE STEEL WOOL!

For the smoothest finish, light sanding between coats is recommended although not always essential. Wait a minimum of 2 hours between coats (75°F [24°C], 50% RH). Sand in the direction of the wood grain and remove dust by vacuum and damp or tack cloth. Ideal temperature is 65°- 80°F (18°C - 27°C). Brush drag may occur when temperatures are too cold or too hot resulting in an uneven application and appearance. Because PolySeal dries fast, care must be taken to avoid lap marks, especially when applying colors. Apply PolySeal at a constant medium rate tempo and always coat the wood section to completion. Don’t stop in the middle! When reloading applicator between brush outs, start 12”-18” ahead of last application and work back to it in order to reduce likelihood of lap marks.

Important–PolySeal may react with tannins and watersoluble extractives found in certain species of wood such as red oak causing a darkening of the wood grain. Also, growing evidence seems to suggest that kiln-dried dimensional lumber (V-match paneling, etc.) that has been wetted by acid rain and then exposed to sunlight may chemically react with water-based varnishes causing blotchy discoloration that follow the pattern of the rain marks. To prevent these occurrences, use White Shellac as a base coat prior to top coating with PolySeal . Always first test a small portion of the wood to be coated with PolySeal to make certain color and appearance is suitable and to confirm that the chemical reactions mentioned above will not occur.

Caution: A slight haze in the PolySeal film can occur if more than one coat is applied too quickly without allowing the previous coat(s) to properly dry. Also, applying too thick of a coat in a single application may cause a similar effect. Do not puddle!

Avoid Prolonged Contact With Alcohol Or Alcohol-based Liquids. Wipe Up Any Alcohol Spills Immediately! Otherwise The Alcohol Can Attack And Damage The Polyseal™ Film And Will Require Sanding And Recoat To Properly Repair And Restore.

Combustible • Contains Petroleum Distillate Solvents, Alcohols, Ketones, Esters, Ethers (Alone or in combination)

See Material Safety Data Sheet

WARNING: Harmful if inhaled or absorbed through skin, causes irritation. Do not breathe vapors or spray mist. Wear an appropriate, properly fitted respirator (NIOSH-MSHA approved) during and after application unless air monitoring demonstratesvapor mist levels are below applicable limits. Follow respirator manufacturer’s directions for respirator use. Avoid contact with eyes, skin and clothing. Wash thoroughly after handling. Keep away from heat and flames. Use with adequate ventilation. Keep containers closed when not in use. In case of spillage, absorb with inert material and dispose of in accordance with applicable regulations.

First Aid: In case of eye contact, flush immediately with plenty of water for at least 15 minutes and get medical attention. For skin, wash thoroughly with soap and water. If affected by inhalation of vapor or spray mist, remove to fresh air. If swallowed, get medical attention. Wash clothing before reuse.

Notice: Reports have associated repeated and prolonged occupational overexposure to solvents with permanent brain and nervous system damage. Intentional misuse by deliberately concentrating and inhaling the contents may be harmful or fatal. Do Not Induce Vomiting.